Solids Separation Equipment

We provide maintained, inspected and quality controlled equipment.

Products on Sale Basis

Solids Separation Equipment

We provide maintained, inspected and quality controlled equipment.

We provide a complete line of solids control and waste management technologies engineered to optimize drilling efficiencies by maintaining fluid integrity, reducing fluid losses, minimizing HSE impact, and lowering drilling costs through NPT management.

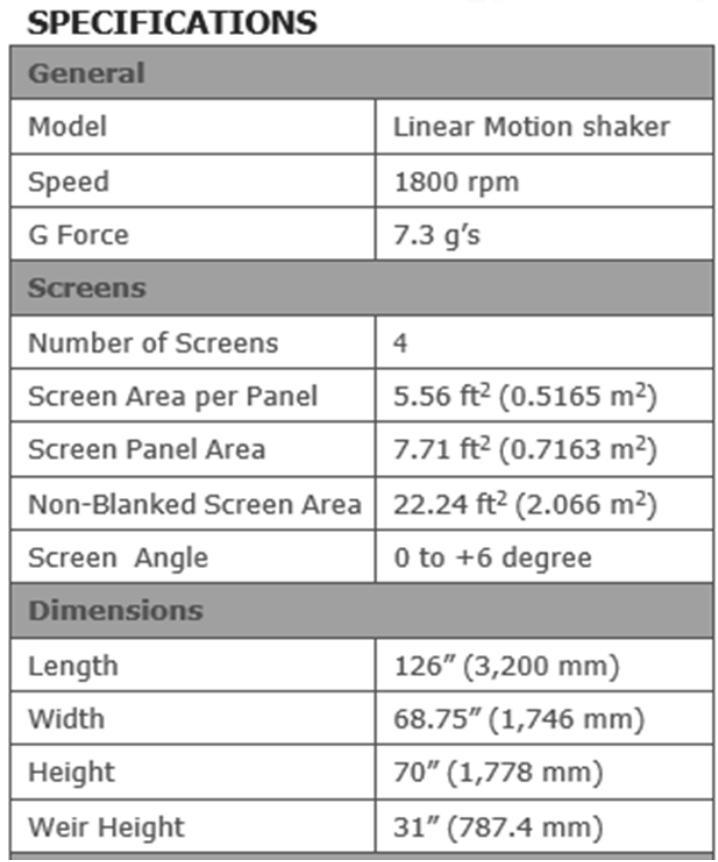

LINEAR MOTION SHALE SHAKER

Linear Motion shale shaker High-performance shakers are specifically designed and engineered to efficiently and reliably separate solids from drilling mud. It produces 7.3 g’s of vibrational force. It has been designed with an impressive 30 ft2 of screening area while maintaining a small equipment footprint. The large screen area of 30 ft2, 7.3 g’s of force and linear motion results in excellent solids conveyance and outstanding performance.

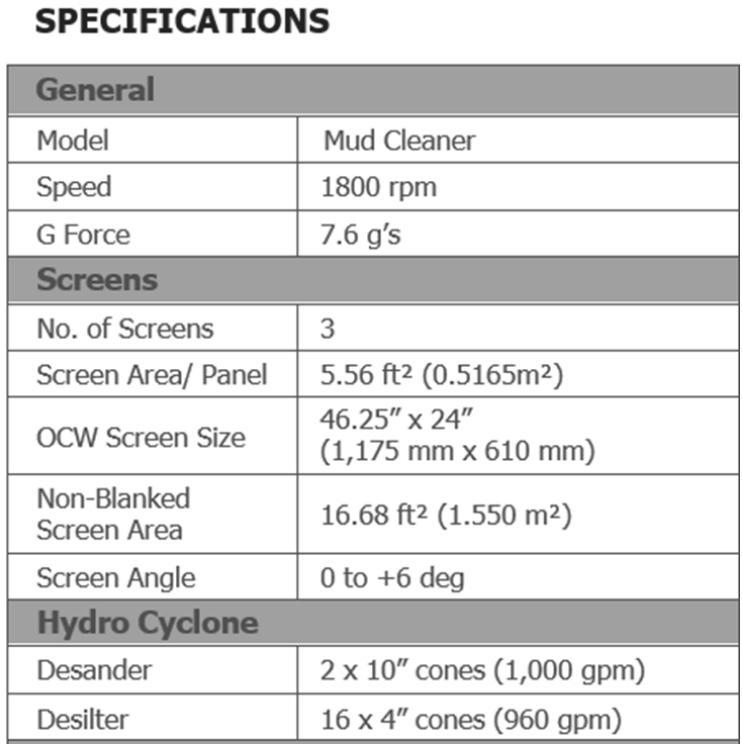

MUD CLEANER

Mud Cleaner uses SVX vibrators which are extremely durable with long life bearings producing less noise. It is a 2 cone 10” desander and 16 cone 4” desilter mounted above a Linear Motion shale shaker which produces 7.6 g’s of vibrational force. The Mud Cleaner has been designed with an impressive 23 ft2 of screening area while maintaining a small equipment footprint. The large screen area of 23 ft2, 7.6 g’s of force and linear motion results in excellent solids conveyance and outstanding performance.

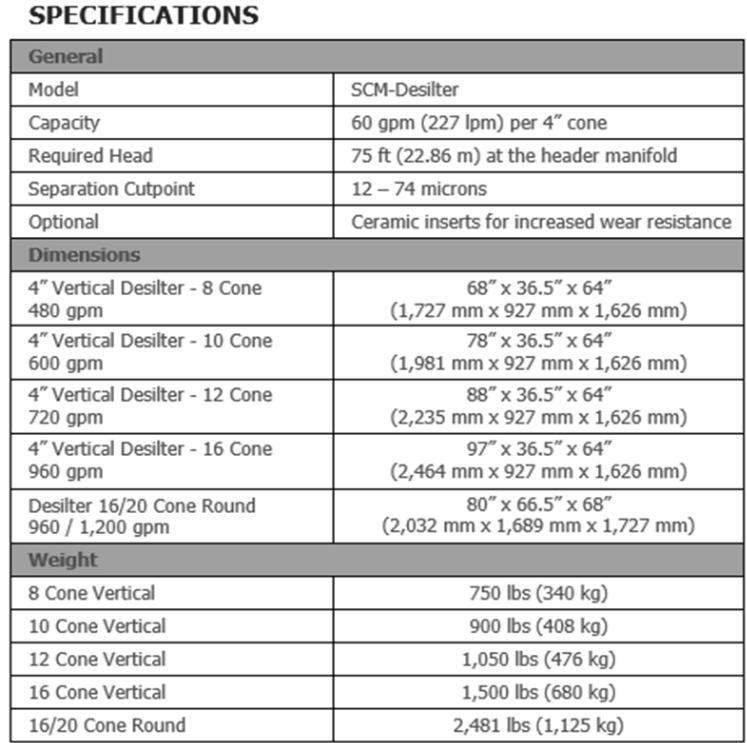

DESILTER

Desilter (4” hydrocyclone) is an integral component of a solids control system providing additional support to the shakers operating at the front line. Each desilter cone has a processing capacity of 60 gpm (227 lpm) and will efficiently remove silt-sized particles from 12 to 74 microns. This equipment is particularly useful during the drilling of larger hole sections where shaker has to be sacrifice to handle the higher flow rates.

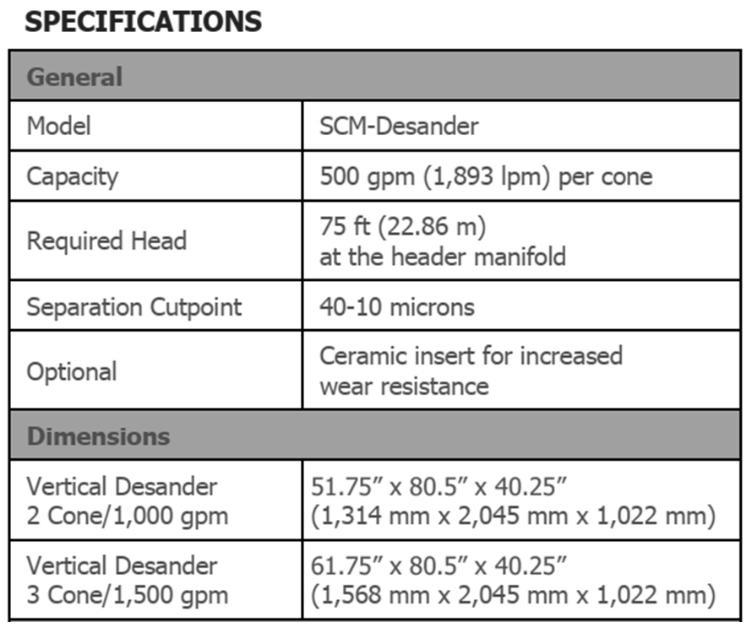

DESANDER

The Desander (10” hydrocyclone) is an integral component of a solids control system providing additional support to the shakers operating at the front line. This equipment is particularly useful during the drilling of larger hole sections where shakers cut point has to be sacrifice to handle the higher mud flow rates. Available in 2 cone – 1,000 gpm / 3,785 lpm and 3 cone – 1,500 gpm / 5,678 lpm configurations.

VACUUM DEGASSER

Desilter (4” hydrocyclone) is an integral component of a solids control system providing additional support to the shakers operating at the front line. Each desilter cone has a processing capacity of 60 gpm (227 lpm) and will efficiently remove silt-sized particles from 12 to 74 microns.

DECANTER CENTRIFUGE

Centrifuge is precision engineered to create high G forces to separate fine solids from oilfield drilling muds and industrial fluids handling applications. bowl and conveyor speed is infinitely adjustable up to 4000 rpm generating 3180 g’s of force providing improved solids removal and reduced drilling fluids costs.

VERTI-G CUTTINGS DRYER

VERTI-G cuttings dryer incorporates a high-speed vertical centrifuge that achieves maximum liquid/solid separation in large-volume processing. This mechanism makes the VERTI-G Cuttings Dryer one of the industry’s best performing and most dependable cutting dryers. The VERTI-G Dryer gives operators a critical advantage in meeting increasingly stringent environmental rules for cuttings disposal.

FEATURES AND BENEFIT

- Maximizing WBM and OBM Drilling Fluid Recovery

- High capacity

- Rotation speeds up 900 RPM with G force to 420 G.

- Waste Solid Declassification.

You may also like

Get in touch with our team to inquire about our Products on Sale

Contact Us