Waste Management

We provide a complete line of waste management services and technologies.

Equipment and Services

Waste Management

We provide a complete line of waste management services and technologies.

Solids Control

Our systems safely remove solids from the drilling fluid. We design, manufacture, and service a comprehensive range of solids-control equipment that includes shale shakers, shaker screens, centrifuges, agitators, degassers, and mud-mixing systems.

Containment and Handling

Our systems safely handle and contain drilling waste. We help you to maintain regulatory compliance and industry best practices with a complete selection of screw conveyors, tank-cleaning systems, containers, pit liners, and tanks.

Treatment and Disposal

We help you to comply with disposal and zero discharge regulations. As part of our Engineered Fluids Management service, we identify the optimal disposal solution by analyzing fluid type, environmental restrictions, and waste streams.

Vertical Cutting Hi-G Dryer

The VERTI-G cuttings dryer incorporates a high-speed vertical centrifuge that maximizes liquid-solid separation in large-volume processing. This mechanism makes the VERTI-G dryer one of the industry’s best performing and most dependable cutting dryers. The cuttings dryer improves overall cost-efficiency, producing reduced amounts of extremely dry cuttings for disposal and recovering valuable fluid for reuse. It is effective with oil and synthetic-base drilling fluids.

Advantages The cuttings dryer is used for reduction of total oil-base mud losses and decrease in waste volumes when drilling wells with the use of oil-base drilling fluids

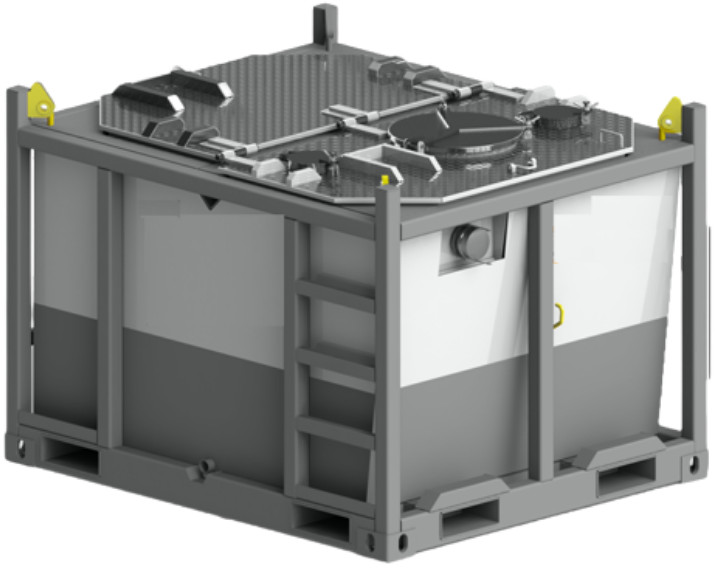

Cuttings Handlings

Cuttings skips are intended for containment and temporary storage of drill cuttings and other drilling waste. Their rugged and reliable design makes them widely used in offshore drilling to meet the most stringent requirements.

Dimensions and Weights

- Length, m 2.2

- Height, m 1.6

- Max Gross Weight, kg11,000

- Effective Volume, m³ 3.8

Due to their compact size and stacking convenience, drill waste collected in skips can be shipped by water, road or railway transport. Cuttings skips can be used in extreme temperatures from -40°C to +50°C without deterioration of strength or integrity.

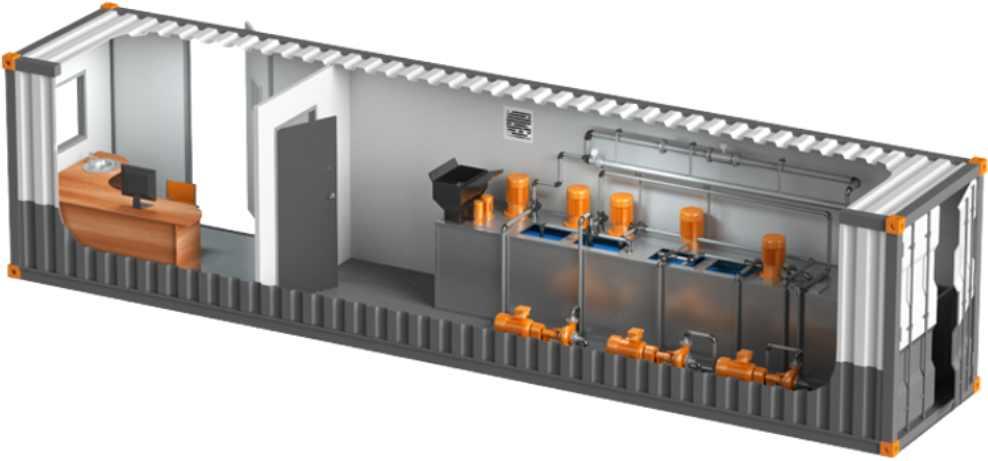

Dewatering System

The dewatering unit function is based on physical and chemical processes of coagulation and flocculation, when fine suspended particles in the treated fluid collide with each other and stick together forming larger particles, which are further removed by the centrifuge. The dewatering unit is designed to reduce drilling waste disposal costs by processing drilling wastes and by recycling water, which can be re-used for making drilling fluids, or for any other technical needs.

The unit is integrated in a standard shipping container, which can be transported by any means of transport, provided all transportation requirements are properly identified and met.

Get in touch with our team to inquire about our Equipment and Services

Contact Us